About Us

Lithium-ion Battery Manufacturing

Building Smarter Batteries for a Smarter Grid

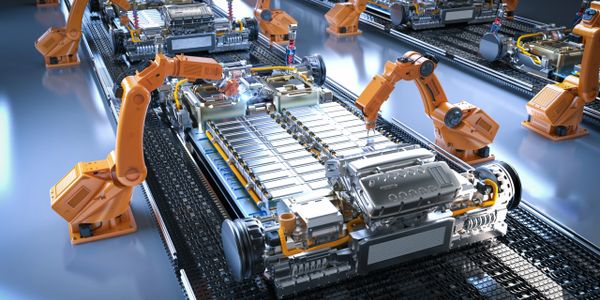

Lithium-ion Battery Manufacturing Equipment and Process

- Our consulting practice delivers end-to-end solutions for advanced lithium-ion battery manufacturing, helping clients move from concept to stable, high-throughput production with confidence. We spearhead the development of next-generation battery manufacturing equipment, fully automated production lines, and tightly integrated Manufacturing Execution Systems (MES) that provide real-time visibility, traceability, and control across the factory floor.

- Working closely with equipment suppliers, automation partners, and internal engineering teams, we design and optimize manufacturing systems for cells, modules, and battery packs, ensuring seamless integration between process technology, automation hardware, and digital platforms. Beyond system design, we drive measurable improvements in end-to-end manufacturing performance by refining process flows, material handling, quality checkpoints, and data architectures—resulting in higher yields, improved product consistency, and enhanced operational stability.

- Our services extend beyond the factory to optimize enterprise-wide operations, including engineering and design, production, warehousing, supply chain, and sales. We align technical capabilities with business processes to improve capacity planning, inventory management, supplier coordination, and cost transparency. By connecting MES, ERP, and planning systems, we enable data-driven decision-making across the organization.

- With deep expertise in battery technology, industrial automation, and operational excellence, we help clients increase efficiency, reduce operating costs, and build scalable, future-ready manufacturing organizations that remain competitive in a rapidly evolving energy storage market.

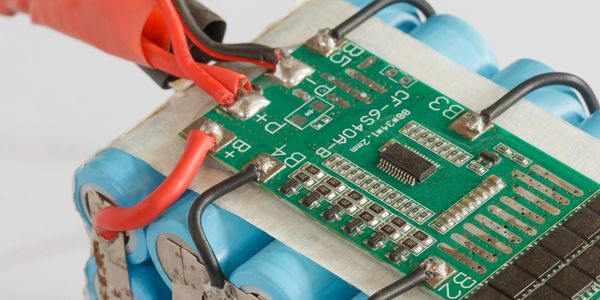

Battery Management Systems (BMS)

- Our consulting services provide comprehensive Battery Management System (BMS) design and development for both mobility and energy-storage applications, supporting clients across the full product lifecycle—from architecture definition to validation and deployment. We help manufacturers and developers build BMS solutions that deliver superior safety, high efficiency, and extended battery cycle life, meeting the demanding requirements of modern battery-powered systems.

- Our team designs robust BMS architectures encompassing hardware, firmware, and system-level integration. This includes cell and pack monitoring, state-of-charge (SOC) and state-of-health (SOH) estimation, thermal management strategies, fault detection, and protection mechanisms. We place strong emphasis on functional safety, compliance with relevant standards, and reliable operation under real-world conditions.

- For mobility applications, our BMS solutions are optimized for performance, fast response, and durability, supporting electric vehicles and other transportation platforms operating under dynamic loads and wide temperature ranges. For stationary energy-storage systems, we focus on long-term reliability, efficiency optimization, and degradation mitigation to maximize asset lifetime and economic returns.

- Beyond technical design, we support system integration with power electronics, inverters, and higher-level energy management platforms. By combining deep expertise in battery chemistry, embedded systems, and application requirements, we enable clients to deploy scalable, high-performance BMS solutions that enhance product reliability, safety, and long-term value in competitive battery markets.

Solar Module Manufacturing

Where Advanced Manufacturing Meets Clean Energy

Solar Module Manufacturing Equipment

- Our consulting services support innovation in high-performance solar module manufacturing, enabling clients to advance toward next-generation photovoltaic (PV) production with confidence and speed. We specialize in driving technology development across manufacturing equipment, automation systems, and production line integration, helping manufacturers achieve higher efficiency, consistency, and scalability.

- We work closely with module manufacturers, equipment suppliers, and automation partners to design and optimize advanced production lines for modern PV technologies. Our expertise spans cell-to-module integration, high-precision handling, lamination, interconnection, inspection, and inline quality control systems. By leveraging advanced automation and data-driven manufacturing practices, we help clients reduce process variability, improve yields, and accelerate ramp-up timelines for new module platforms.

- A core focus of our approach is ensuring that manufacturing innovation translates into operational excellence. We optimize equipment selection, line layout, throughput balancing, and digital integration to support stable, high-volume production. Through the integration of manufacturing execution systems (MES), inline testing, and real-time process monitoring, we enable continuous improvement and rapid issue resolution across the factory floor.

- With deep technical knowledge of PV technologies and industrial automation, we act as a strategic partner for manufacturers pursuing next-generation solar module production. Our consulting services help clients build future-ready factories that deliver bankable, high-performance modules while maintaining cost competitiveness in a rapidly evolving global solar market.

Solar Module Manufacturing Facility

- Our consulting services provide end-to-end support for solar module manufacturing facility build-up, guiding clients through every stage from initial planning to full operational readiness. We help manufacturers make informed decisions starting with site and location selection, evaluating factors such as logistics, utilities, labor availability, incentives, and regulatory requirements to ensure long-term operational and financial viability.

- Once a location is defined, we lead the facility and factory design process, aligning production capacity targets, technology roadmaps, and automation strategies with building layouts and infrastructure requirements. Our team advises on equipment selection and procurement, working closely with global equipment suppliers to ensure optimal performance, scalability, and cost efficiency. We also develop detailed equipment layout and line configuration plans, optimizing material flow, space utilization, and production throughput.

- Our expertise extends to MEP (mechanical, electrical, and plumbing) consulting, including power distribution, clean and dry air systems, HVAC, water and wastewater management, and fire protection systems—ensuring compliance with local codes while supporting high-efficiency, stable manufacturing operations.

- By integrating facility design, process engineering, and utility planning into a unified execution strategy, we help clients reduce construction risk, shorten ramp-up timelines, and control capital and operating costs. The result is a future-ready solar module manufacturing facility designed for reliable, scalable, and competitive PV production.

Data Center

Infrastructure for the Data-Driven World

Site Acquisition

- Our consulting services specialize in data center site acquisition and powered land development, helping clients secure locations that are fundamentally aligned with the demanding requirements of modern digital infrastructure. We identify, source, and develop sites with robust power availability, redundancy, and long-term scalability, enabling data center projects to move forward with reduced risk and accelerated timelines.

- We begin with strategic site identification and acquisition, focusing on regions with favorable grid access, transmission capacity, utility engagement, and regulatory environments. Our team evaluates both greenfield and brownfield opportunities, prioritizing powered land or sites with clear, bankable pathways to power delivery. Through comprehensive property and infrastructure due diligence, we assess zoning, environmental constraints, geotechnical conditions, utility interconnection, and entitlement readiness to ensure development certainty.

- A key differentiator of our approach is the integration of power strategy into site development. We work closely with utilities, independent power providers, and energy partners to structure reliable power solutions that meet uptime, redundancy, and expansion requirements. This includes evaluating grid resiliency, substation access, backup generation, and future load growth potential.

- By combining deep expertise in infrastructure development with disciplined site acquisition and power planning, we help clients secure mission-critical data center locations that support high-density compute, long-term growth, and operational resilience in an increasingly power-constrained market.

EPC (Engineering, Procurement, Construction)

- Our consulting services provide comprehensive turnkey project execution for data centers and high-technology facilities, managing every phase from conceptual engineering to final commissioning. We guide clients through complex projects with an integrated approach that combines engineering excellence, procurement expertise, and construction management to deliver facilities on time, within budget, and to the highest quality standards.

- Our engineering services cover MEP (mechanical, electrical, and plumbing) system design, structural analysis, and BIM (Building Information Modeling) coordination, enabling seamless integration of complex systems and reducing design conflicts before construction. We optimize layouts, ensure compliance with codes and industry standards, and plan for future scalability and operational efficiency.

- Through our global procurement network, we source high-reliability components—including transformers, PDUs, and ASICs—ensuring competitive costs without compromising performance or delivery timelines. Our construction management team oversees critical path schedules, enforces OSHA safety standards, implements quality control protocols, and provides real-time reporting via advanced project management platforms, keeping stakeholders informed at every stage.

- We specialize in fast-track delivery for hyperscale and edge facilities, balancing speed with precision to meet the demands of today’s digital infrastructure. By integrating engineering, procurement, and construction expertise, we help clients turn complex projects into operationally ready, high-performance facilities that support long-term growth and reliability.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.